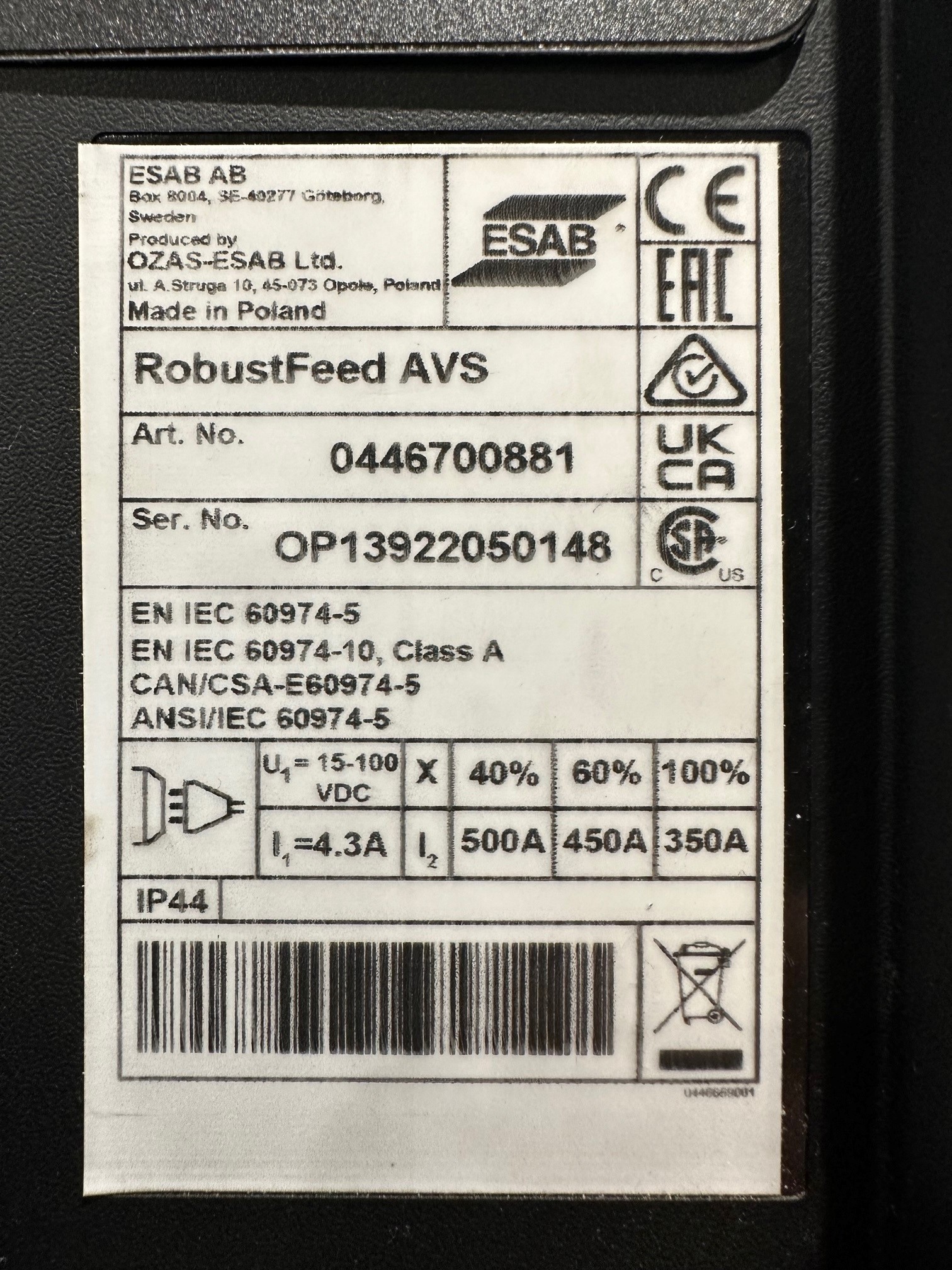

500amp ESAB Robust Feed AVS voltage-sensor wire feeder

In Stock - Hire Now! ✓

Download Spec Sheet (pdf)In stock for sale @ £2,500 + VAT inc. 3 years warranty, and available to hire.

The Robust Feed AVS ‘Arc Voltage Sensing’ wire feeder is the best voltage-sensing MIG wire feeder ever made, and can be used with any CC and CV welder power supply, whether it’s a multi-process MIG / MMA stick 500amp inverter welder, or even a 200amp CC 110V stick welder!

Note. The pictures in the portfolio were taken with a standard ‘un-insulated’ earth reference clamp. We actually supply a fully insulated 400amp reference lead clamp (like what you find on car battery boosters) with our voltage-sensor MIG feeders, as well as a 7mtr x 16mm² black rubber insulated copper cable.

The reason for needing an insulated reference clamp (that is plugged into the wire feeder), is that if you touch the metal of the earth lead clamp (which is plugged into the ‘-‘ Dinse socket) and the metal of the wire feeder reference lead clamp (feeder plugged into the ‘+’ Dinse socket, and reference lead plugged into feeder), at the same time with bare hands (without wearing gloves), you will get a 56V electric shock. When each of the ‘-‘ supply earth and ‘+’ supply Robust Feed AVS reference clamp is clamped onto the steel job to be welder, the voltage disappears instantly and transferred into the material, as the electric circuit has been created providing power to the feeder / MIG torch. When handling the clamps at the same time, electricity will take the shortest route, which is through your arms!

We tried every single make and model welding machine and diesel welder generator we had in stock, including all our petrol and diesel welder generators, ESAB, Jasic, Lincoln Electric, Miller, and Thermal Arc MIG and 415V stick welders, and we found that VRD (voltage reduction device) does not work and reduce voltage down to a safe 8 volts, on any welding machine when cables are plugged into positive and negative. Every welding machine had 56 volts OCV going to the cable ends, expect the Jasic MIG 350 and 450, which had a higher 67 volts OCV.

After all compatibility trails were conducted, we were staggered. This Robust Feed AVS was tried and tested on all our 200amp, 300amp, 400amp, and 500amp diesel welder generators (on CC and CV – diesel welder generators has OCV on CV mode unlike 415V welders) and all our 110V, 240V, and 415V MMA stick and MIG welders, on CC stick mode, and it works perfectly. This really is something spectacular, because MIG welding can now be done using any welding machine power source!

Note. OCV voltage-sensing reference lead feeders like the Robust Feed AVS, don’t work on 415V MIG welders on the welding machine’s standard CV MIG mode. This is because on standard CV there is no 56 volt supply going down the ‘+’ welding cable, and instead the OCV goes down an interlink controller cable (ie. a reduced 48V constant voltage down the multi-core plug and Amphenol) to the machines ‘standard’ powered wire feeder.

A standard ‘non-voltage sensing’ MIFG feeder is limited by a dedicated -pre-existing 5 or 10mtr interconnection cable length. The beauty of this air cooled Robust Feed AVS, is that you can swap out the pre-existing welding machine feeder and it’s interlink, and use this voltage-sensing feeder even at 90 mtrs away from the power source (ie. 6x 15mtr copper welding cable extensions on the earth, and 6x 15mtr copper welding cable extensions for the feeder), with 15mtr argon hose extension leads connected together, for massive amounts of reach when working on difficult to access sites ie. taking the feeder through tight man holes, up high towers, and far away from the 415V power supply etc.

When the welder power source is on CC stick welder mode however, the welding machine redirects the open circuit voltage down the ‘+’ electrode and ‘-‘ earth cables, to power the Robust Feed AVS voltage-sensing feeder.

The ESAB Warrior 400 and 500 when on ‘Mobile Feed CV‘ mode, are the only 415V welder power source that can power a voltage-sensing feeder like a diesel welder generator. This OCV CV feature mode is for certain other model voltage-sensor wire feeders that struggle (and blow up) when powered on CC constant current.

This is because there is no 56 volt supply on CV, and the feeder requires the open circuit voltage on ‘Constant Current’ (stick welder mode) to power it.

ESAB ‘Mobile Feed CV‘ mode, is the same as a Lincoln Electric Ranger 305D, Vantage 410, and Arc Gen Weldmaker 500 diesel welder generator when on CV MIG mode.