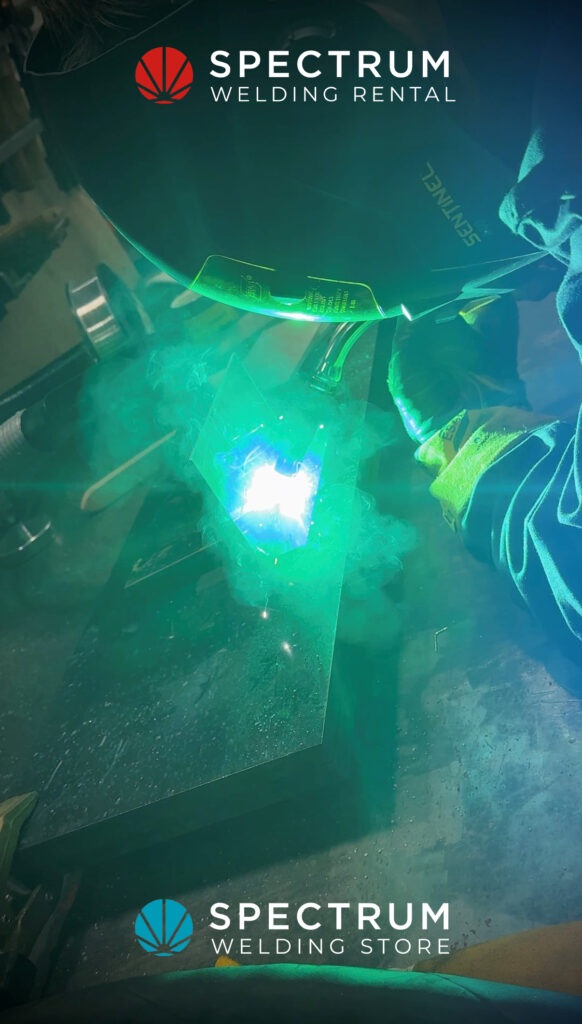

Joe goes to… weld 5356 aluminium

TO HIRE EDGE 500 @ £250 p/week

Email us to set an account up and hire straight away.

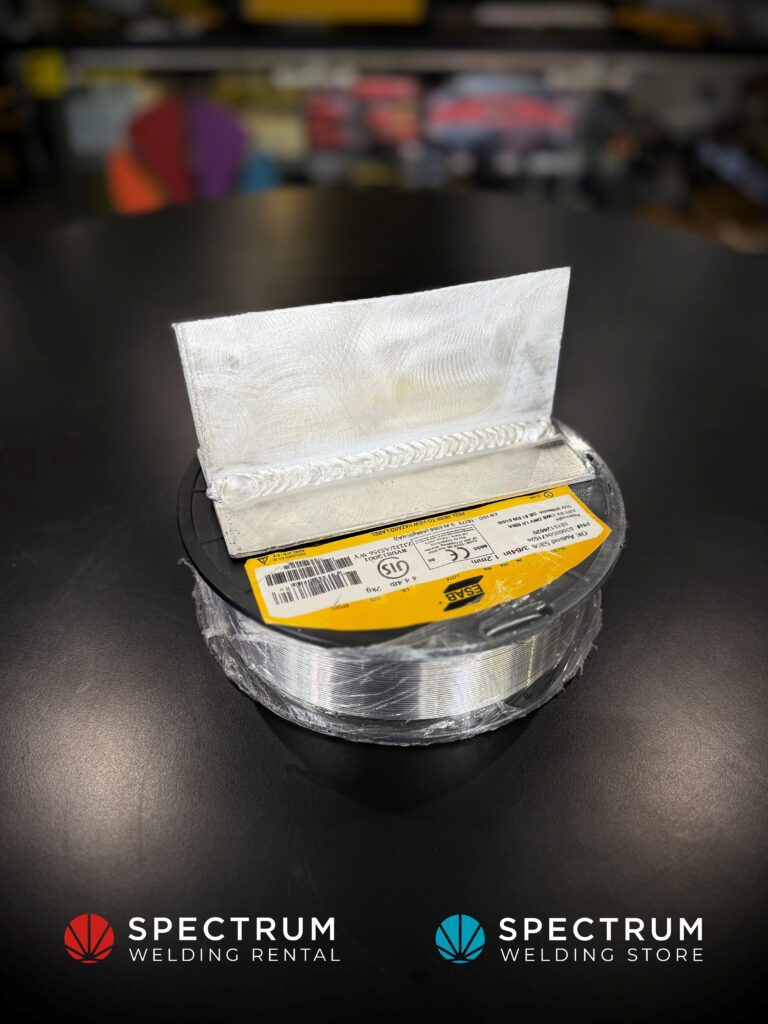

ESAB Warrior Edge pulsed MIG welding 5356 aluminium 1.2mm wire. Read our LinkedIn post here.

It’s just a great machine to be honest, and we enjoy playing with it and learning how it works and reacts. So easy to use, even makes me look a little bit almost good.

I think the Edge will do away with a lot of AC TIG welding applications due to being so quick, easy, no spatter, aesthetically pleasing, and with reduced heat input. This new design pulse process is here now, it exists, and ESAB got it spot on. Compared to previous pulsed MIG processes we’ve tried over the years since pulse first came out, this 2025 Edge MIG is in a different league.

It takes the skill out of the job and almost does the weld for you. I think it will also do away with the majority of standard non-pulse MIG welding spool-on-gun jobs, because you can just push / carry your RobustFeed wire feeder around (on a 10mtr interlink cable reach) and it’ll feed 1.2mm perfectly down a 4mtr torch with zero snagging or resistance created. Continuous feed is crucial for aluminium. So 14mtrs total of water cooled reach from the Edge pulse power source to weld pool.

So yea, the Exeor torch can feed aluminium at any angle in knots upside down hanging off edges and drooping, and weld all day, which is what operators need. Reliability, consistency, and nice welds.