The best MIG Welder for Welding Pipe

The ESAB Warrior Edge 500 DX: The Best MIG Welder for Pipe Welding

Pipe root gap welding presents unique challenges that demand precision, control, and advanced technology to achieve consistent, high-quality results. The ESAB Warrior Edge 500 DX meets and exceeds these requirements, making it one of the best MIG welders for pipe welding on the market today. With cutting-edge features like the ROOT process, advanced pulse settings, and Speed mode, the Warrior Edge 500 DX delivers unmatched performance for pipe welders.

Key Features That Make the Warrior DX Perfect for Pipe Welding

ROOT Process: Seamless Control for Gap Bridging

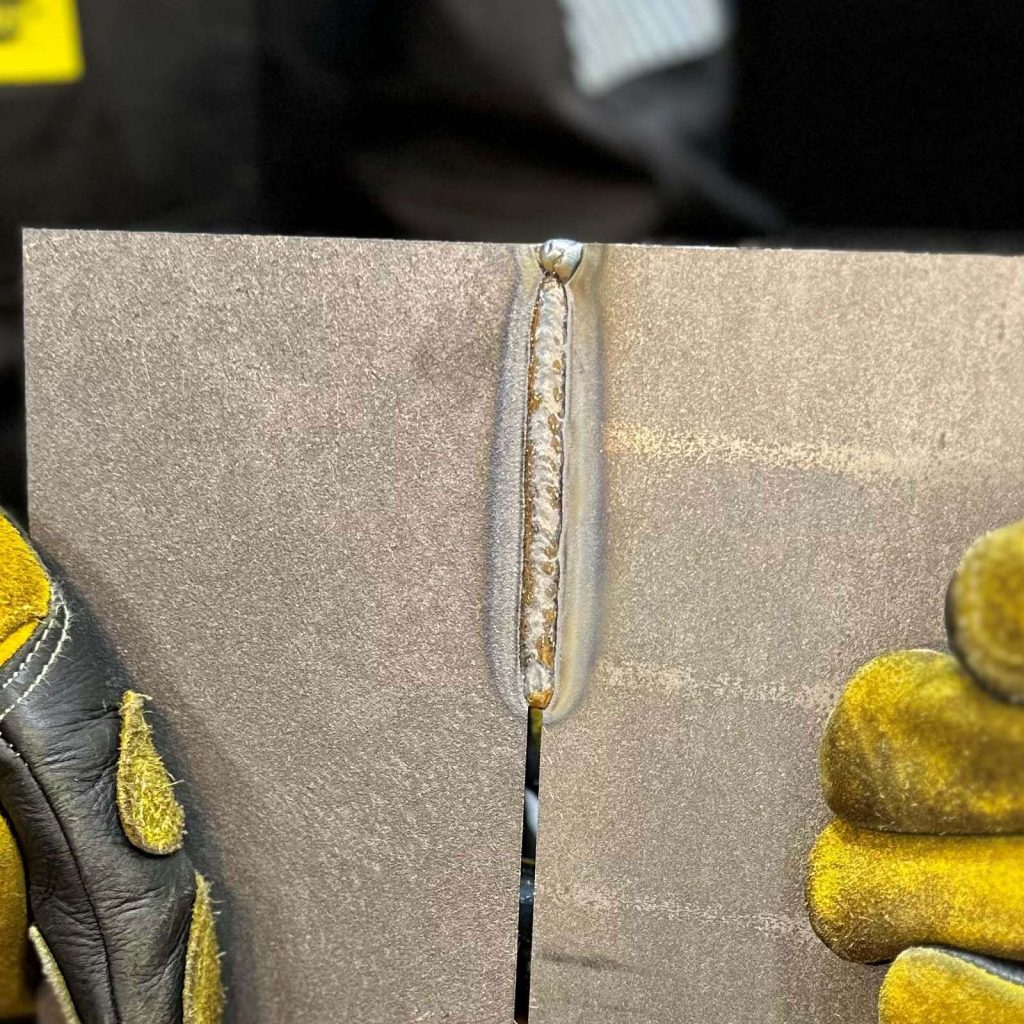

One of the standout features of the Warrior Edge 500 DX is its ROOT process, which is specifically optimized for pipe root welding. This technology provides exceptional control during root passes, allowing for:

- Precise Gap Bridging: The ROOT process can bridge gaps up to 25 mm wide without blasting through.

- Instant Set: The arc sets instantly over the gap, ensuring a flawless weld even over voids of thin air (with perfect penetration from the front and the back of the weld).

This capability is critical in pipe root welding, where maintaining the integrity of the root pass is essential for strength and penetration of the weld. Blowing through a pipe root is a serious problem when you can’t get to the back of it to repair! So utilising a genius process like ROOT that allows for ultimate and reliable control, is as essential as it gets. The ROOT process also means you can MAG weld pipe now without needing to do a TIG root pass. TIG root pass is clean, neat, and controlled, but extremely timely, and very skilled work. The Edge ROOT process however is equally as clean, very easy to use, and infinity quicker when you have lots of vertical up and down root gap to fill.

SEE PIPE ROOT SPEC SHEET DOWNLOAD

Advanced Pulse Settings for Customizable Arcs

The machine offers advanced ‘Arc Dynamics‘ pulse parameter controls, enabling welders to fine-tune arc characteristics for softer or harder arcs depending on the application. This ensures:

- Optimal Penetration: The ability to control penetration precisely means that the weld is strong without risking burn-through.

- Cleaner Welds: Minimal spatter reduces post-weld cleanup, saving time and effort.

Speed Mode: Minimized Heat and Distortion

The Speed mode on the Warrior Edge DX is designed for high-deposition welding, delivering:

- Targeted Penetration: The weld is deep and secure without excessive heat input.

- Reduced Heat-Affected Zones: Minimizing heat distortion is crucial for pipe welding, where warped sections can compromise the pipe’s structural integrity.

Why the Warrior Edge 500 DX Excels in Pipe Welding

No Blasting Through: A Huge Advantage for Pipe Welding

A major issue in pipe welding is the risk of the weld blasting through the pipe wall, especially on root passes. Once the weld blasts through, it’s nearly impossible to access and fix the damage from the inside of the pipe. The Warrior Edge 500 DX’s ROOT process solves this problem:

- The controlled arc ensures that the weld penetrates securely without burning through.

- This precision makes it ideal for all-position pipe welding, where access to the inside of the pipe is restricted.

By avoiding blow-through, the Warrior Edge 500 DX not only saves time but also prevents costly rework, making it a go-to solution for professional pipe welders.

Enhanced Safety and User Experience

- Safer Welding: Reduced spatter and lower fume emissions create a safer working environment, especially in enclosed pipe welding spaces.

- User-Friendly Interface: The intuitive controls allow for quick parameter adjustments, making it accessible for both novice and experienced welders.

Conclusion: The Ultimate Pipe Welding Solution

The ESAB Warrior Edge 500 DX is purpose-built to tackle the toughest challenges in pipe welding. Its advanced ROOT process eliminates the risk of burn-through, its pulse settings provide precision and control, and its Speed mode ensures efficiency with minimal distortion. For professional welders, these features translate into time savings, improved safety, and the confidence of delivering flawless welds every time.

Whether you’re welding small pipes or tackling industrial-scale projects, the Warrior Edge 500 DX is the ultimate tool for getting the job done right. Contact us today to see it in action or learn more about how it can revolutionize your welding operations.

Spectrum: Setting the Standard in Welding Excellence.