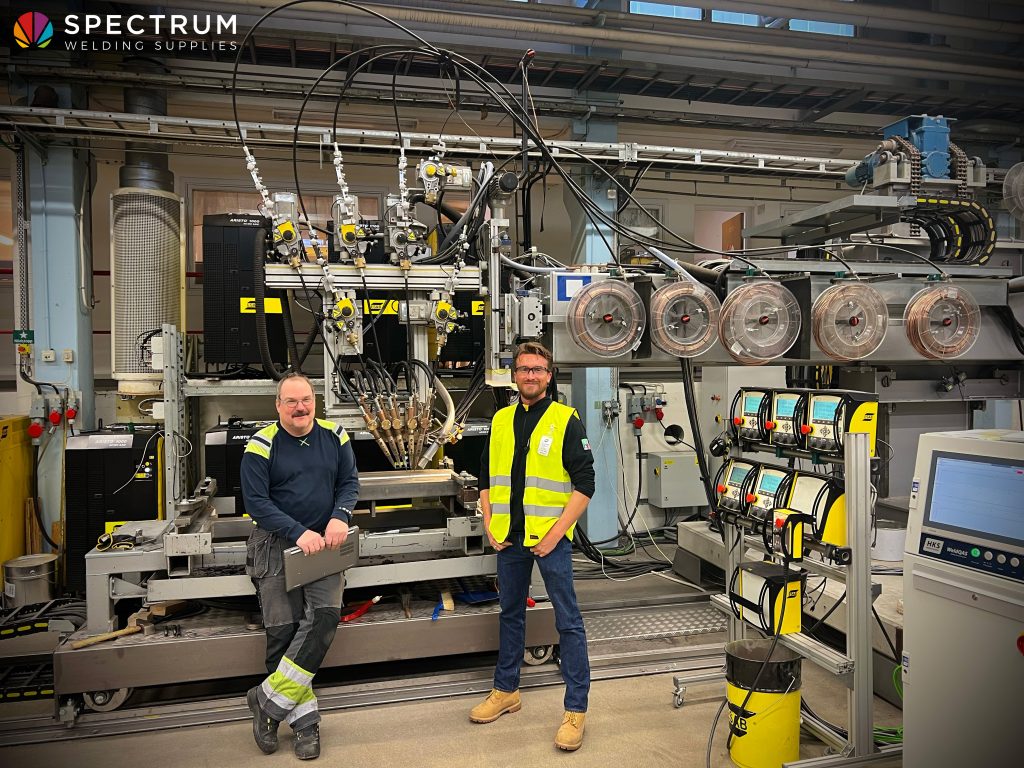

Joe goes to ESAB Sweden Head Office

ESAB very kindly invited me out to their heavy fabrication manufacturing facility in Laxå, Sweden. The Union Jack flag outside the factory was raised for my arrival, and they were the most welcoming, accommodating, kind, and wonderful people. I’ve loved every second (see LinkedIn post).

My eyes have been opened in many ways by what ESAB as a company are, the holistic approach they adopt to solving a problem with pure quality, and their vast premium product range. ESAB Automation Capital Goods represents a commitment to welding excellence, with a truly talented and experienced team, who are able to weld anything imaginable.

Direct Access to ESAB technology

What I’ve been reminded of from my trip is the importance of using and seeing the equipment myself first-hand. Every question was answered, with ESAB being the supportive supplier, and partner, I’ve come to love.

When it comes to engineering challenges, ESAB are simply the best of the best. They have the knowledge, experience, facilities, and expert team, to quite literally solve any problem, with a genius solution.

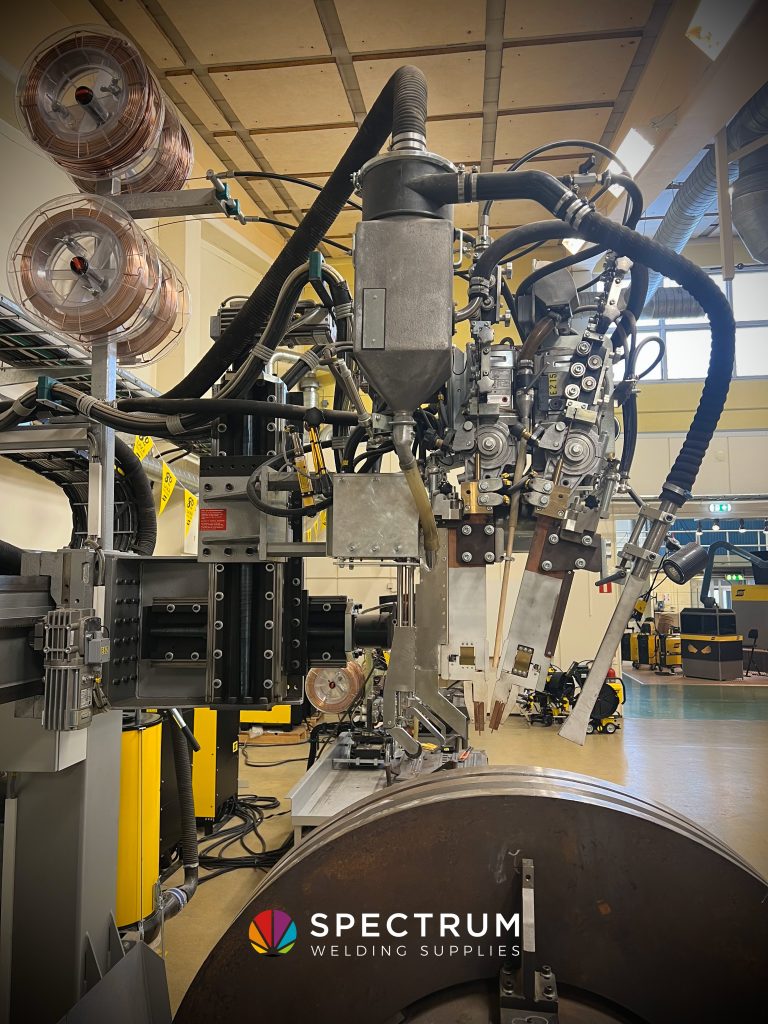

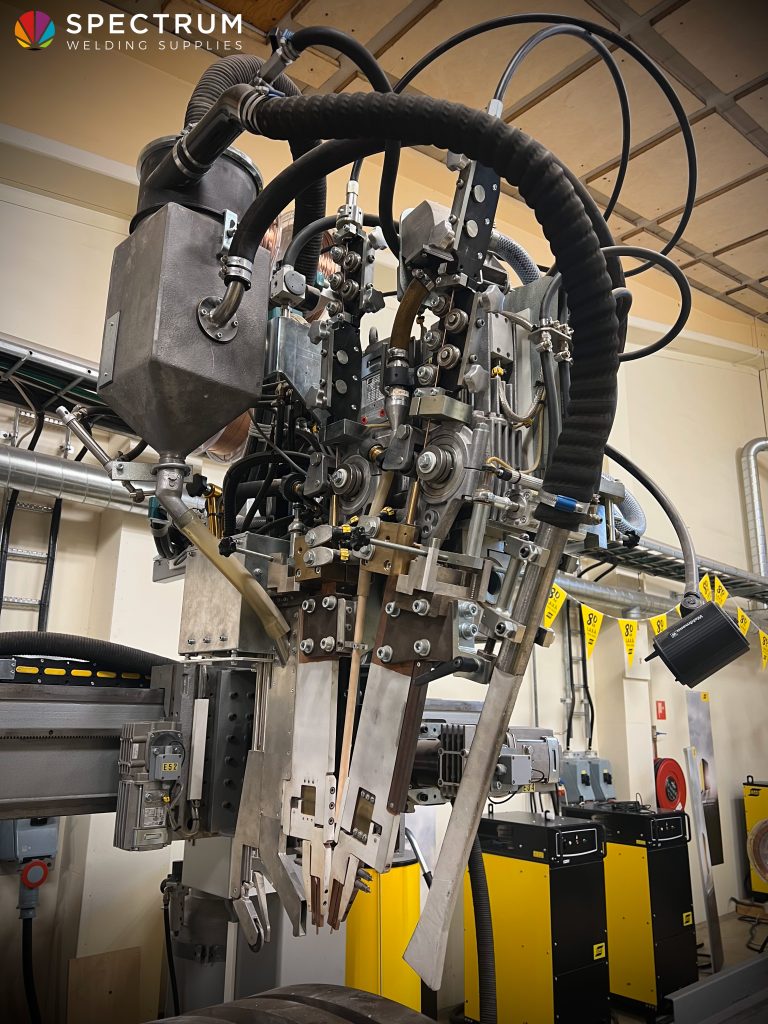

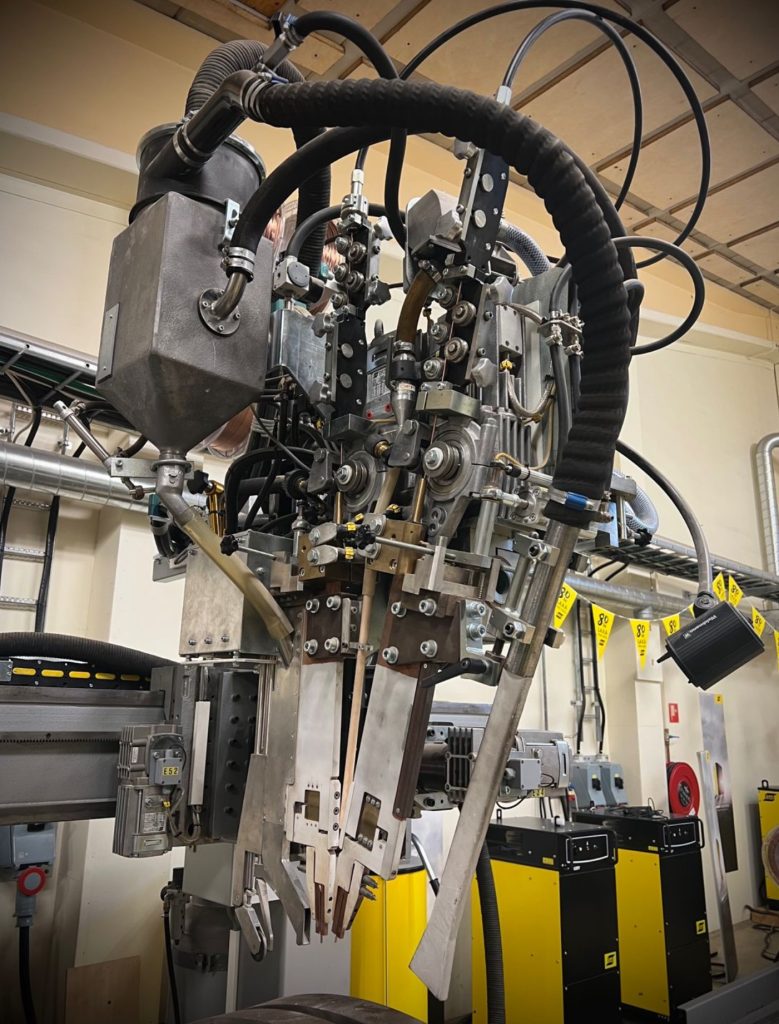

Seeing the beautiful and overwhelmingly stunning HNG Multi narrow gap head was sublime. Witnessing the sub arc ICE™ welding process for the first time up close, was the stuff of science fiction. The process is mind-blowing, and can speedily dump 40kg per hour of perfect weld deposition material, into a massive weld prep joint. It is designed for the heavy fabrication side of our industry, conscientious of protecting the strength and integrity of the base metal from weld heat imput ☢️

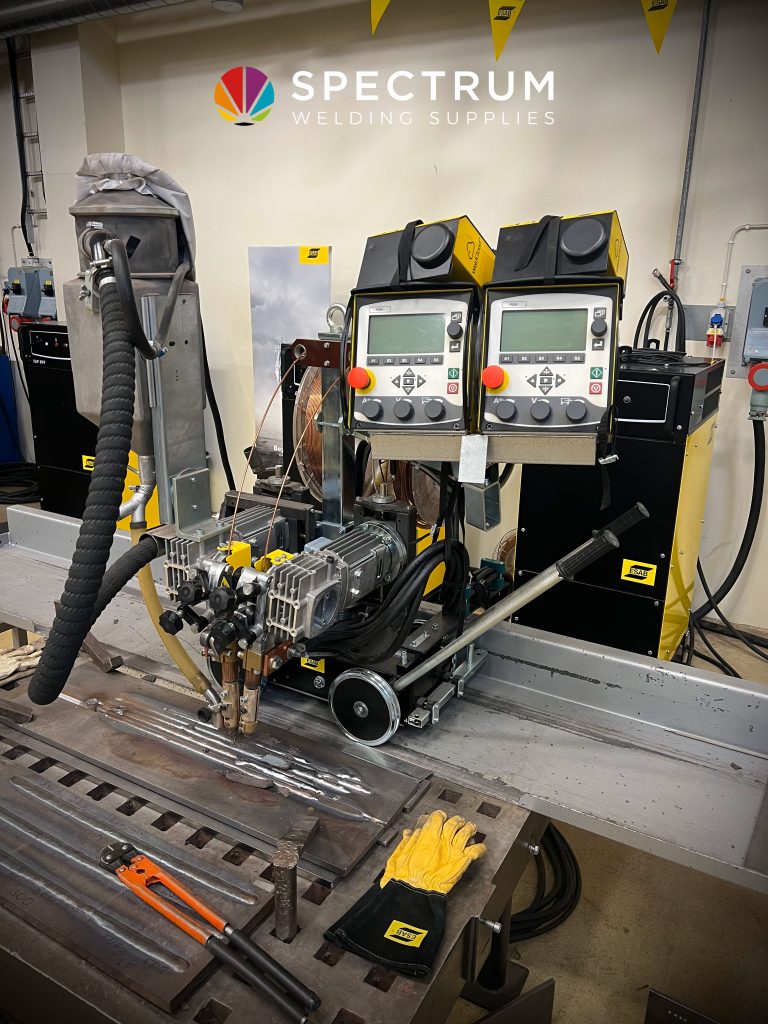

The ESAB research team walked me through their findings, and future plans to enhance their automated welding science discoveries 🔬The research analysis team at Laxå, study every possible weld parameter, setting, and configuration, explaining to me in detail what the welding machine was doing and why. It’s made me realise how good their behind the scenes team is.

The lengths ESAB go to help a customer, really is second to none. They have an innate desire to understand not only the product implicitly, but the potential the science of it can deliver for that customer’s application. ESAB R&D are constantly looking ahead at making the best, even better, which has been put at the forefront of my mind. The tour was outstanding, and the ESAB laboratory where technology is created, is a wonderful thing to witness. There is an unrelenting and unwavering dedication to understanding every element of the physics and chemistry of welding, on the grandest and most impressive platform.

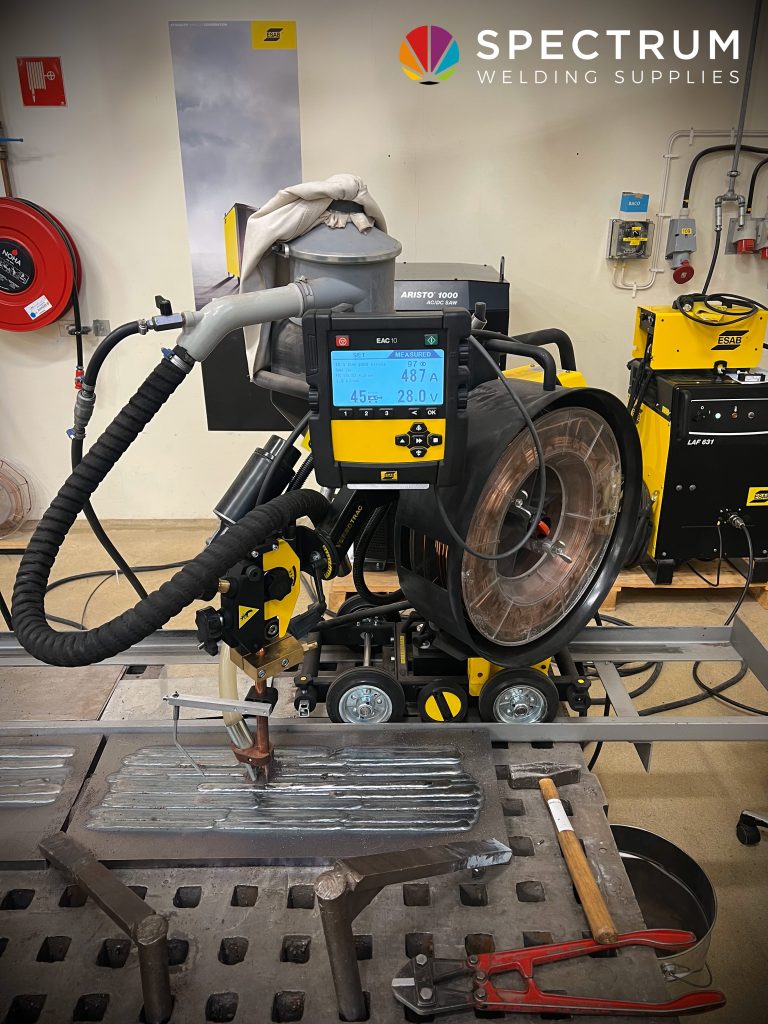

The ESAB Aristo 1000 AC/DC inverter power source alone, is capable of increasing and speeding up weld production by approx. 20%, just by tweaking the balance settings, compared to conventional sub arc welders. These are no-brainier automated production solutions for our customers, who want to invest in state-of-the-art, efficient machinery.

It really has been an unbelievable honour, and I can’t say thanks enough.

There are some very exciting things to come.