Product Description

- Amps: 1250amps

- Stud capacity: 3 – 12mm

- Stud length capacity: 5 – 8mm

- Supply voltage: 415V 3-phase

- Current Load: 40amps @ full power

- MCB fuse trip required: D-rated

- Weight: 220kg

- kVA rating: 70 kVA

- Generator needed to power: 100 kVA

NOTE:

- 32amp 4 or 5-pin plug works perfectly up to M10 / 80% power

- 63amp plug required for full power drawn arc stud welding M12 stainless / copper studs

- Although this machine can weld M16 studs, the gun is only setup for up to M12

Penetration Depth

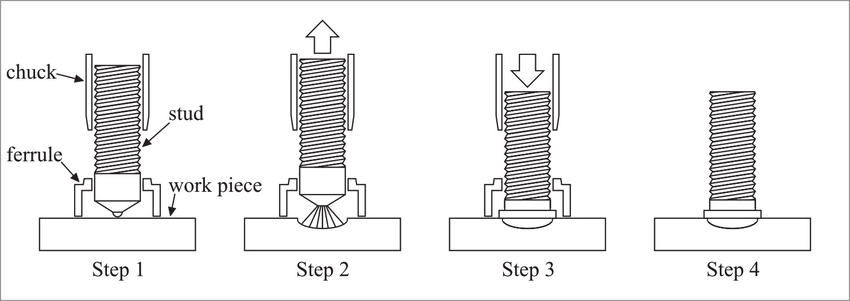

Drawn arc stud welding involves a slightly longer setup time, and increased weld time due to the higher heat input, however this allows for deeper penetration into the base material. This results in a stronger bond between the stud and the workpiece, compared to a capacitor discharge ‘CD’ stud welding.

Weld Pool Size

The larger weld pool created by drawn arc ‘ DA’ welding provides a greater surface area for the stud to fuse with the base material, enhancing the overall strength of the joint.

Material Thickness

Drawn arc welding is suitable for thinner and mainly thicker materials, as it can create a robust weld even on heavy-duty applications.

Weld Quality

The drawn arc process allows for better control over the welding parameters, leading to higher quality and more consistent welds. It also accommodates larger diameter and longer studs, which can contribute to increased joint strength.

Application Versatility

Drawn arc welding can be used with a wider range of materials and stud sizes, making it more versatile for various industrial applications where strength is a priority.

Capacitor discharge welding on the other hand is faster and generates less heat, making it ideal for applications where minimal distortion and heat-affected zones are required, such as in electronics or thin sheet metal work.