UK’s and Europe’s Largest Fleet of Weld Positioning Equipment

Established 42 years ago Spectrum has built up the one of the UK’s largest fleet of positioning welding equipment and automated sub arc tractor welders. Importantly to note, we are also equipment setup experts, offering advanced procedural guidance to ensure your welds are flawless.

Telephone: 01246 205 267

Types of Welding Positioning Equipment

Here is a comprehensive list of equipment used for positioning welds to ensure proper alignment and access during automated welding operations.

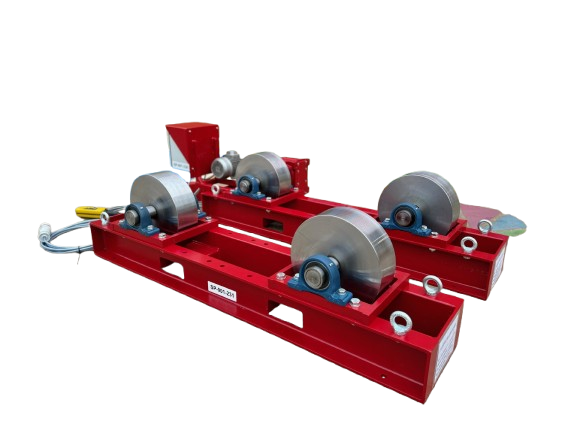

Rotating Equipment

- Conventional welding rotators are used to rotate all thing cylindrical. This includes pipes, pressure vessels, silos, storage tanks, and positions for circumferential, longitudinal and specific point of access welds. The whole purpose is for controlled automated welding.

- Self-Aligning Welding Rotators ‘SAR‘ adjust wheel centres automatically to the size and weight of the workpiece.

- The SAR model reduces denting by spreading the load across extra wheels, and cusps further up the cylinder side wall to maintain the shell shape, preventing bellying out.

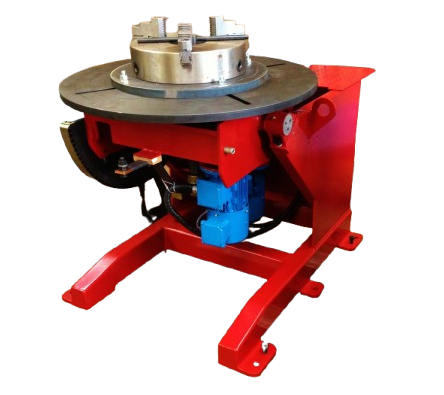

Lift, Tilt, and Turning Positioners

- Equipment with tilt, rotate, and lift capabilities for positioning steel into optimal weld angles.

- Allow controlled rotation of workpieces for consistent welding.

Positioner Clamping and Fixturing

Modular Jig Bracket Systems

- Reconfigurable clamps and brackets for diverse welding setups.

- 3-jaw and 4-jaw chucks are specifically designed to align and secure pipes and attachments.

- Flat plate jaws are used for extra wide jobs that need to be clamped out at the edges of wide positioner tables.

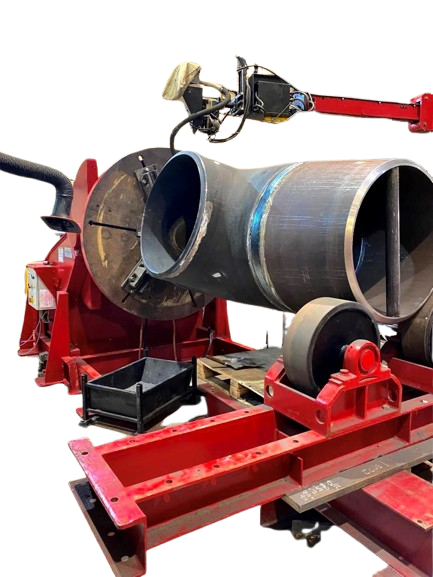

Column and Boom Welding Manipulators

- Up / Down / Left / Right adjustable boom arm that maneuvers the welding tip into a fixed position within the weld prep ie. for circumferential or longitudinal welds.

Alignment Tools for automated welding

- Laser lamps ensure precise workpiece alignment for welding such as ESAB A6 Arc Master and Versotrac submerged arc welding heads.

- ESAB GMH Joint Tracker with probe and powered slides system is the perfect solution to prevent ‘drifting’, and ensures guaranteed runs along the prep line.

These tools and equipment are essential for ensuring high-quality welds by improving access, accuracy, efficiency, and consistency.

All in stock here at Spectrum Welding Supplies Ltd, Chesterfield UK.