Product Description

This material is commonly used with oxy/acetylene torches on bronze, brass, copper, and copper alloys, for tasks like repairing cracks in castings.

Generally, you don’t need to use flux, but Sifbronze Flux can help the material flow better when working with dirty or oxidized copper.

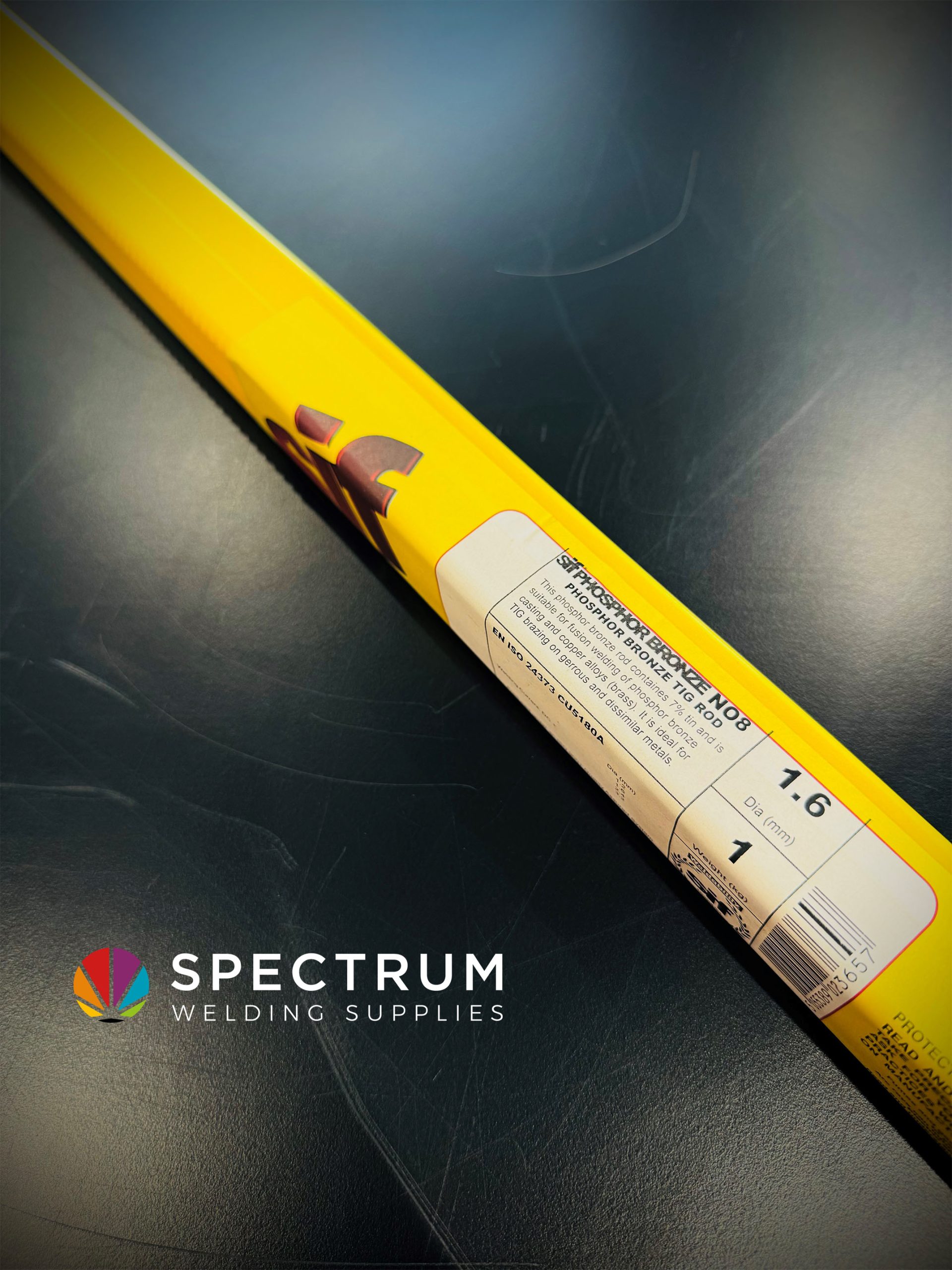

If the base metal has trace amounts of lead (like in LG2), it’s best to use Sifphosphor Bronze No. 8 for TIG brazing.

Reviews

There are no reviews yet.