Product Description

- Warrior Edge 500 CX Synergic Pulse Water Cooled MIG welder

- RobustFeed Edge wire feeder

- 10m interlink cable 70mm²

- 3m x 6mm² 4-core SY power supply cable fitted

- On wheels with bottle trolley

- MB501 x 3m or 4mtr water cooled MIG torch

- 600amp x 5mtr 70mm² earth lead c/w Myking screw-type clamp

- 3mtr 20bar 6mm ID 3/8th nut argon hose

- 415V 32amp 4 or 5-pin red plug

- Assembled

- Weld tested

SETUP FOR EITHER OF THE BELOW:

- 4x, 1.0mm – 1.2mm V-Groove solid wire MIG wire drive rollers

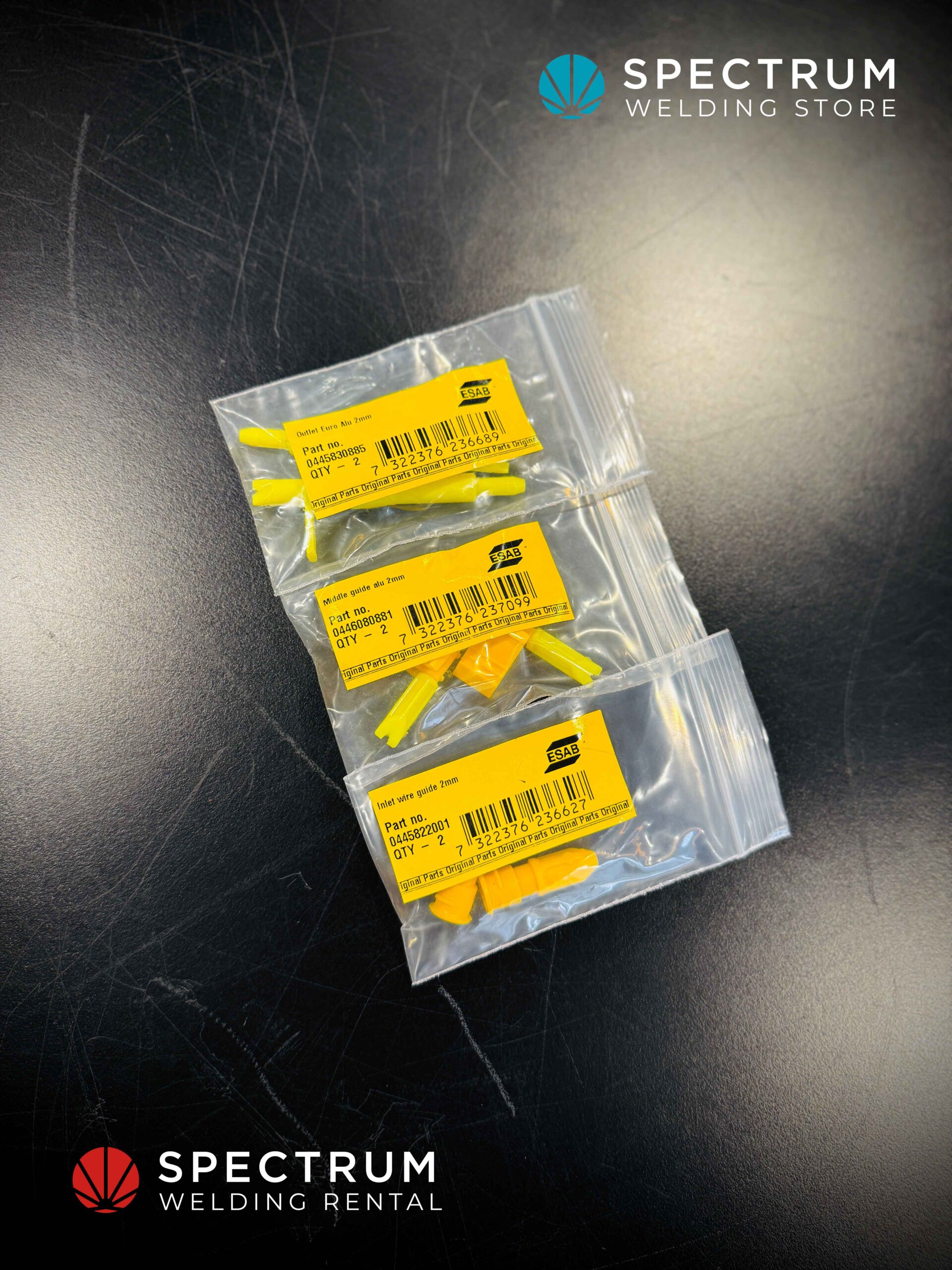

- 4x, 1.2mm U-Groove aluminium wire MIG wire drive rollers

- 4x, 1.2mm knurled serrated groove flux-cored MIG wire drive rollers

- Synergic Pulse MIG, Synergic MIG, SPEED, Manual MIG, MMA stick

- Duty rating @ 100% – 400 amps

- Duty rating @ 60% – 500 amps

- Pulls 3-phase 30amps @ 500amps full power

- 32amp MCB D-rated trip needed

- Adaptive optimized PULSE MIG process that compensates for operator variation with an easy, user-friendly setup designed to achieve excellent weld results.

- New feature SPEED provides a focused arc that allows the welder to better and easier handle the weld puddle at much higher travel speeds, deeper focused penetration, increasing the productivity, reducing HAZ dilution rate (base metal weakening by heat distortion), whilst maximising penetration.

NOTE. Always perform a quick 5 second ‘TRUEARC compensate‘ (done from the digital feeder menu) on the steel before welding. You do this if changing torch, position of wire feeder and interlink cable, or adjusting earth lead cable / cable length. This is an auto calibration inductance reset, that super tunes the Warrior Edge cable resistance feedback, to achieve the best synergic settings.

Joe Fitzpatrick –

The Warrior Edge 500 ‘CX II’ model @ £8,000, is specifically designed for mild steel and stainless. This comes with Digital Gas and Speed, with the Speed feature producing mind-blowing results on mild steel (subject to the thickness and material). We’ve used the pulse MIG mode to welding 316 LSi, Neo Nickel 253, and 2209 duplex, and the results were flawless.

You couldn’t wish for better welds, and that is what the Warrior Edge is all about. It can tackle everything, anywhere, whether it’s general day to mild steel fabrication, or a nuclear reactor, this is the machine to do it.

The Warrior Edge ‘DX’ model @ £10,000 which comes out in 2024, will have all the additional features made available, such as aluminium MIG, Root (which is STT for pipe root), Deep, Thin, and Vertical. The DX will be for tackling any and all weird and wonderful materials and applications that need special settings, for gauranteed results. Root settings for pipe welding will be a game changer, and is a modern equivalent to Lincoln Electric STT (Surface Tension Transfer). Root parameters will vastly increase pipe productivty, improve penetration results without blowng through, and make life easier when welding pipe preps (TIG root hot pass still required subject to application).

The below is a short summary of what the Warrior Edge 500 CX II welder (with ‘Digital Gas’ and ‘Speed’ settings) and WeldCloud system represents, moving forward into a new era of modern technology. This package is where the future of welding and fabrication is going, because it makes life easy, and adds a new level of professionalism that didn’t exist before. The information you’d gather from ESAB’s WeldCloud (connected to the Warrior Edge machine) is fascinating, and a lot can be learned about how a job is being welded. WeldCloud is especially helpful if you are working to a lot of weld procedures, or want to start incorporating and monitoring more weld procedures, with a software that sees everything.

1. The ESAB Warrior Edge is the best MIG welder on the market for any thickness (best penetration / lower dilution rates / faster welds / higher deposition rates), and is the ultimate approach to improving everything that can be.

2. WeldCloud will fully document and track welds, proving and confirming correct penetration welds are put into every prep.

3. WeldCloud will give you insight into every aspect of what the Warrior Edge is doing each day / week / month ie. kg deposited and minutes used etc.

4. WeldCloud is much quicker method of producing traceability data.

5. Full backup, support, and training from Spectrum and ESAB.