Product Description

- Warrior Edge 500 DX Synergic Pulse Water Cooled MIG welder

- RobustFeed Edge wire feeder

- 10m interlink cable 70mm²

- 3m x 6mm² 4-core SY power supply cable fitted

- On wheels with bottle trolley

- MB501 x 3m or 4mtr water cooled MIG torch

- 600amp x 5mtr 70mm² earth lead c/w Myking screw-type clamp

- 3mtr 20bar 6mm ID 3/8th nut argon hose

- 415V 32amp 4 or 5-pin red plug

- Assembled

- Weld tested

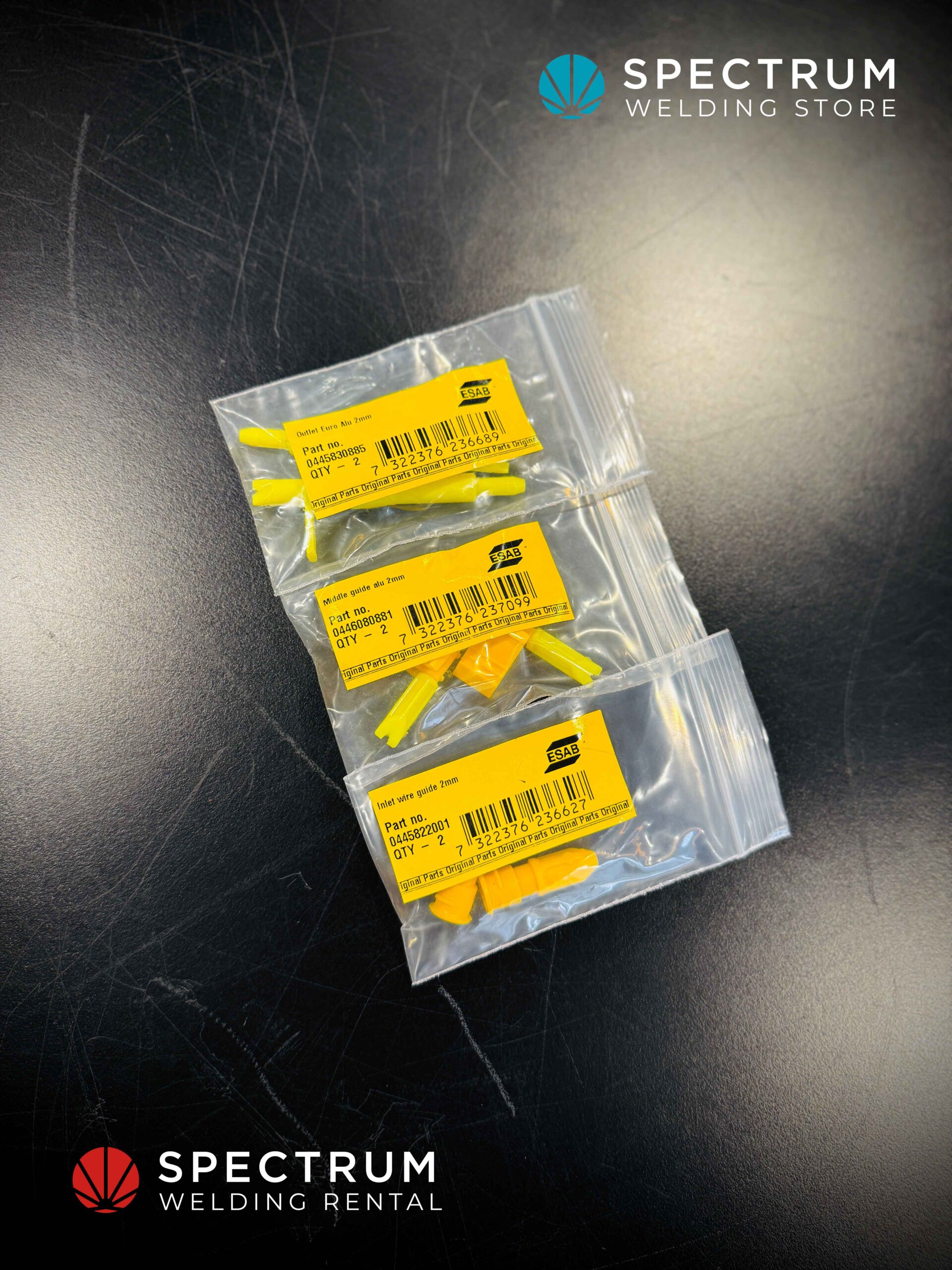

SETUP FOR EITHER OF THE BELOW:

- 4x, 1.0mm – 1.2mm V-Groove solid wire MIG wire drive rollers

- 4x, 1.2mm U-Groove aluminium wire MIG wire drive rollers

- 4x, 1.2mm knurled serrated groove flux-cored MIG wire drive rollers

- Synergic Pulse MIG, Synergic MIG, ROOT, CRAFT, THIN, SPEED, Manual MIG, MMA stick

- Duty rating @ 100% – 400 amps

- Duty rating @ 60% – 500 amps

- Pulls 3-phase 30amps @ 500amps full power

- 32amp MCB D-rated trip needed

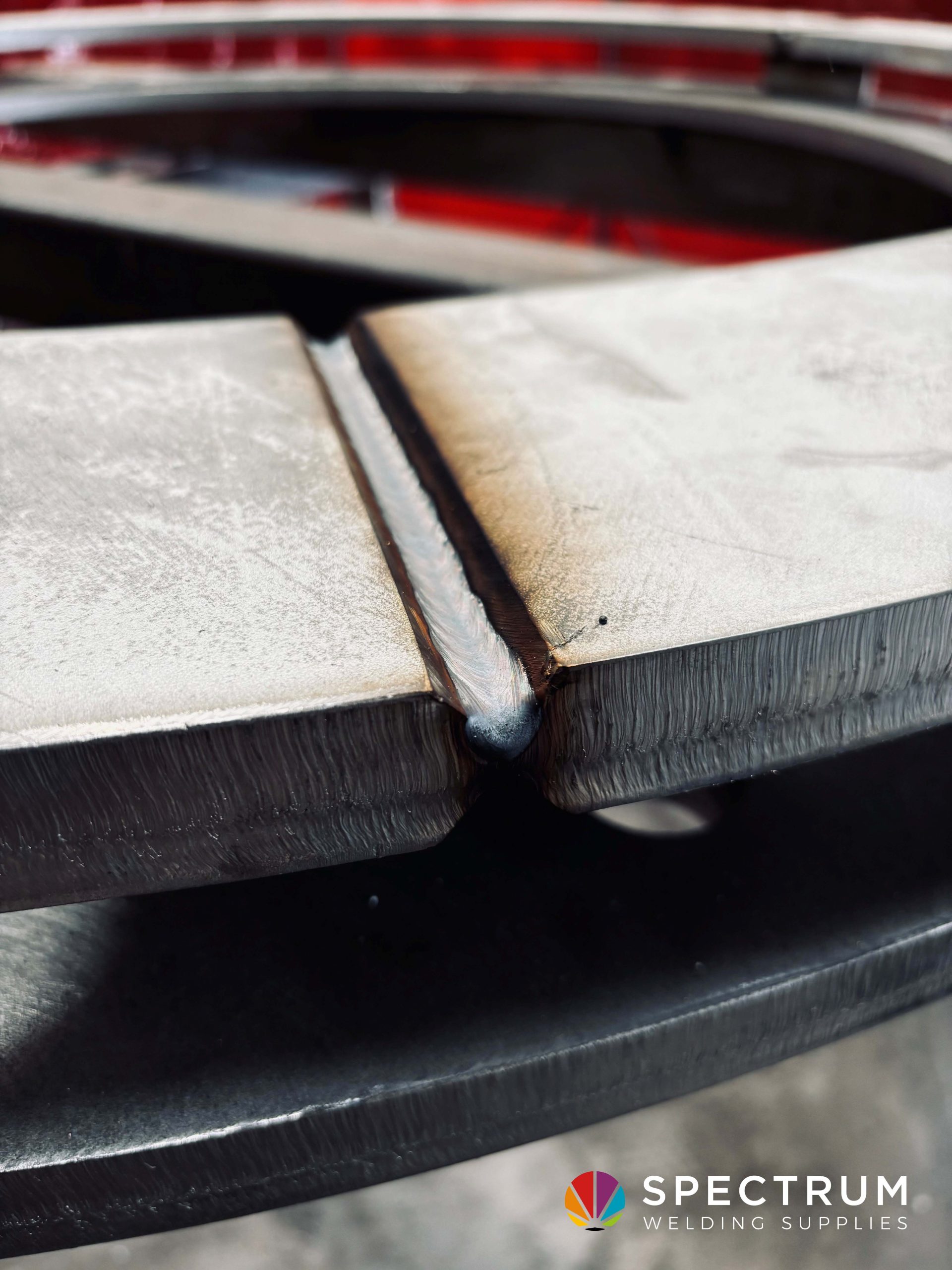

The Warrior Edge DX is the best pulsed MIG welder in the world… by far. See 4043 aluminium 1.2mm wire pulse MIG welds here using the Warrior Edge.

Available with either 5, 10 or interlink length (all in stock here at Spectrum Chesterfield).

We have the UK’s largest rental fleet of the Edge DX in stock, and have never seen results as good when using the pulsed settings on stainless and aluminium. ROOT process is also beyond words and bizarre to witness (crazy how it works). Spectrum will help you get dialed in straight away with the exact Arc Dynamic, volts, amps, and trim settings for any and every material you’re wanting to weld, to the highest standard imaginable.

The Warrior Edge DX is the full-blooded flagship model with every and all feature, including:

- Premium pulsed settings for all grades and variations of mild steel, stainless, duplex, inconel 625, 310 chromium nickel, and aluminium.

- ROOT process, which is a mind-blowing way to weld pipe root (like Lincoln Electric STT Surface Tension Transfer, but better) or used to bridge prep up to 25mm wide with solid wire on vertical up! (yes, it is actually unbelievable and sets instantly). Click here and here to see ROOT results in our workshop.

- SPEED process, for ultra fast high deposition and low dilution welds, with targeted penetration and vastly reduced heat affected zones (yes, this process literally ticks every box a welder could ever want).

- THIN process, which is a fast process for MIG welding super thin stainless. THIN has the ability to replace welding jobs that typically require intricate stainless TIG welding, which can be very slow and unpractical when needing to welds lots of the same parts.

- CRAFT process, which is twin-pulse for ultra clean spatter free aluminium welds. Amazing on thin stainless steel (looks like TIG).

- DEEP processes to follow mid-2026 (only available on the DX model).

The digital control panel on the inside of Robust Feed Edge is incredibly user-friendly, and you’ll be up and running within minutes. After seeing how much the Edge can articulate a weld with Arc Dynamics and give you access to fine tune the physics of the weld pool, you’ll never want to go back to an old school normal MIG welder again. It’s a genuine joy to weld with.

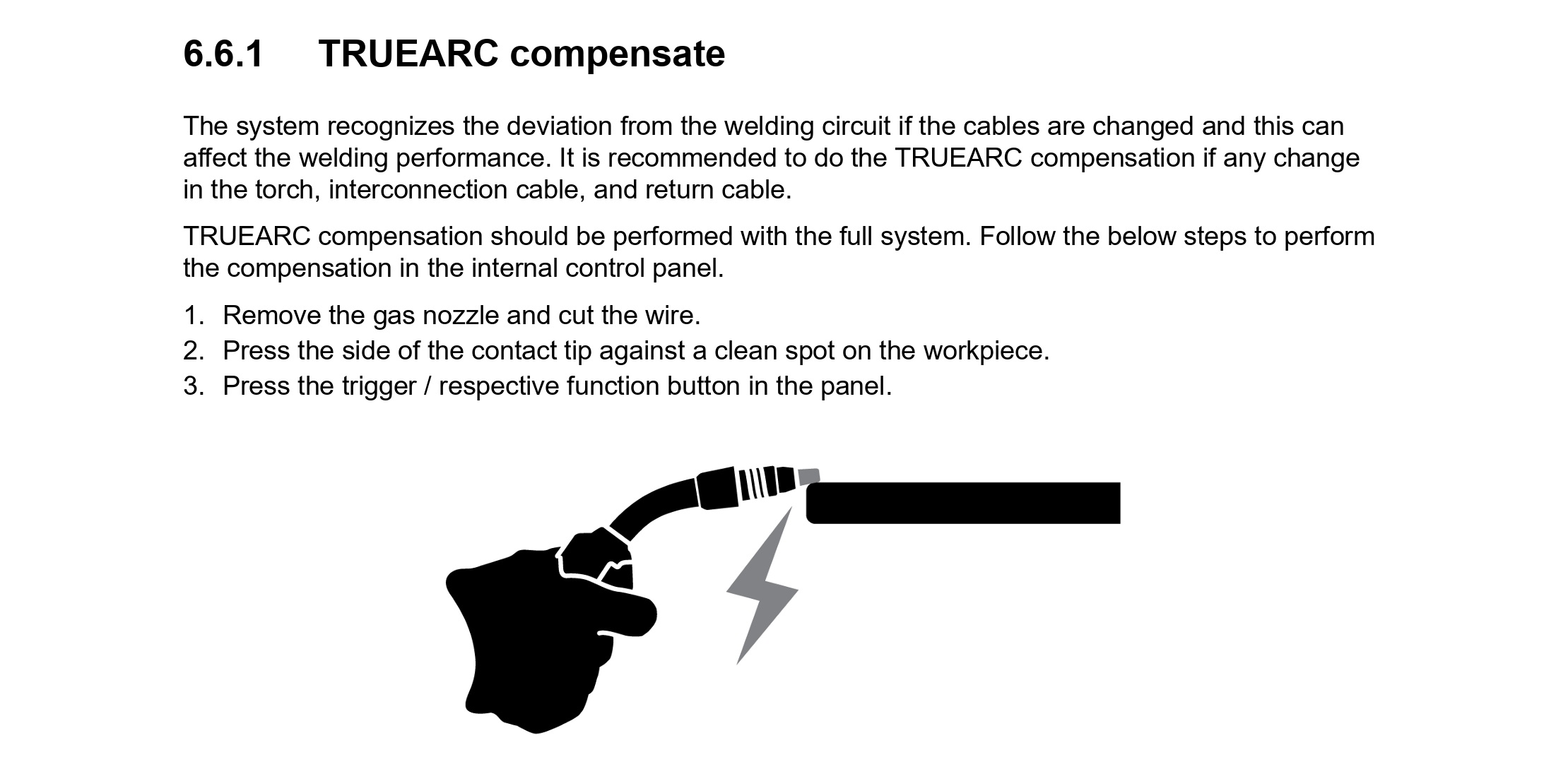

NOTE. Always perform a quick 5 second ‘TRUEARC compensate‘ (done from the digital feeder menu) on the steel before welding. You do this if changing torch, position of wire feeder and interlink cable, or adjusting earth lead cable / cable length. This is an auto calibration inductance reset, that super tunes the Warrior Edge cable resistance feedback, to achieve the best synergic settings.