Massive and wide ranging stock

of new, used and hire machines

Submerged Arc Specialist Suppliers

Expertise for setup and training

Welding Rotator Hire

The UK’s leading supplier of pipe / welding rotators

At Spectrum we have a huge range of welding rotators for hire.

- From 1 tonne to 100 tonne capacity

- Conventional welding rotators

- Self aligning welding rotators

- Scissor welding rotators

Usually available and delivered within 24 hours.

Hire from the UK smartest welding supplier

Spectrum: 01246 205 267

-

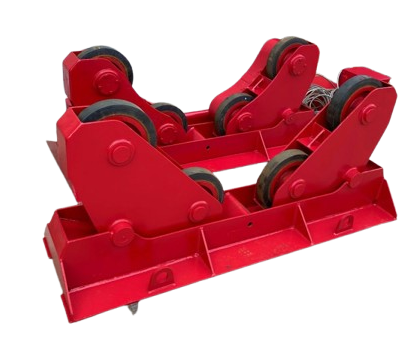

2 tonne scissor pipe rotator for hire

Read more -

5 tonne scissor pipe welding rotators for hire

Read more -

3 tonne self-aligning pipe welding rotators for hire

Read more -

5 tonne self-aligning pipe welding rotators for hire

Read more -

10 tonne self aligning welding rotators for hire

Read more -

10 tonne NARROW self-aligning welding rotators for hire

Read more -

15 tonne self aligning welding rotators for hire

Read more -

20 tonne self aligning welding rotators for hire

Read more -

30 tonne self aligning welding rotators for hire

Read more -

50 tonne self aligning welding rotators for hire

Read more -

60 tonne self aligning welding rotators for hire

Read more -

100 tonne self aligning welding rotator for hire

Read more -

1 tonne pipe welding rotators for hire

Read more -

3 tonne welding rotators for hire

Read more -

5 tonne welding rotators for hire

Read more -

5 tonne STEEL WHEEL welding rotators for hire

Read more -

10 tonne welding rotators for hire

Read more -

10 tonne STEEL WHEEL welding rotators for hire

Read more -

20 tonne welding rotators for hire

Read more -

30 tonne welding rotators for hire

Read more -

60 tonne welding rotators for hire

Read more -

100 tonne welding rotators for hire

Read more

1. Conventional Rotators (CR)

What they are

Twin-drive “traditional” turning rolls with fixed wheel centres. Spectrum carries rental sets from 1 t right up to 100 t, in both rubber-tyred and steel-wheel formats.

When they shine

| Scenario | Why CR is the sweet spot |

|---|---|

| Uniform-diameter pipe or vessels | Fixed-centre rolls don’t need to adjust once you’re set; you get rock-solid tracking. |

| Heavy wall / high loads | Steel-wheel options withstand point loading and heat soak during multi-pass SAW. |

| Procedures that mandate low capital cost | At £50–£400 p/w the CR line is the most economical in Spectrum’s fleet. |

Pro tip – If you’re working with clad or polished shells, specify the rubber-lagged wheels; they give enough compliance to avoid surface bruising without losing traction.

2. Self-Aligning Rotators (SAR)

What they are

Four-wheel bogies mounted on a pivoting cradle. As the shell lands, the wheels toe in or out so the vessel centres itself automatically. Spectrum’s SAR hire range runs from 3 t to a monster 100 t, including narrow-wheel versions for thin-wall chimneys.

When they shine

| Scenario | Why pick SAR |

|---|---|

| Mixed-diameter production (e.g., 900 mm followed by 1 600 mm) | Auto-centre saves 5-10 min of roll-spreading per change-over. |

| Cones, barrels or vessels with light TIR | The wheels pivot to keep all four tyres in contact, stopping the job “walking”. |

| Thin-wall or soft alloys | Wider contact patch spreads the load and cuts the risk of ovality. |

Set-up note – Because the drive and idler adapt to diameter, you can run paired vessels back-to-back in the same bay without swapping gear, just tweak the inverter speed.

3. Scissor (Height-Adjustable) Rotators

What they are

Low-capacity (2 t & 5 t) pipe rollers mounted on a scissor lift so you can jack the workpiece up off the deck. Key design aims are quick centre-height change and clearance under flanges or base plates.

When they shine

| Scenario | Why the scissor wins |

|---|---|

| Small-bore spool fabrication | Brings the weld seam up to a comfortable TIG-torch height—no back strain. |

| Flanged spool pieces / base-plate pipe | Lift clears the protrusion so the wheel rims don’t foul. |

| Rapid shot-blast / paint turn-round | You can tilt the scissor a touch, drain runs of primer, then drop it back for welding—without a crane. |

Heads-up – The scissor frames are only rated to 2 t or 5 t; if you’re moving into 6 mm-plus wall thickness, step up to a 3 t SAR set instead.

Quick-reference selection flow

-

Is the load > 5 t?

Yes → Jump to CR (uniform shells) or SAR (mixed shells). -

Are diameters changing batch-to-batch?

Yes → SAR. -

Need height adjustment or base-plate clearance?

Yes → Scissor. -

Otherwise → CR (cheapest & simplest).

Final thoughts

Spectrum’s hire stock is broad enough that you can scale from shop-floor spool work all the way to 100-tonne pressure-vessel builds without leaving one supplier. The pages also list weekly hire rates, so it’s easy to cost each option into a tender. When in doubt, ring their applications desk—those lads will tell you how many drive vs. idler bogies you need for any given weld-procedure spec.

Stay smooth and keep the roll turning.