Product Description

BENEFITS OF FLUX-CORED WIRE ON MILD STEEL INCLUDE:

- Smooth appearance: The excellent wetting helps produce flat, smooth weld beads (this is a much more advanced wire than solid wire)

- Minimal post-weld dressing: No spatter and favourable bead shape, often reducing the need for grinding or other post weld cleanup

- Superior fusion: Provide excellent fusion at the root joint and sidewalls (even in vertical)

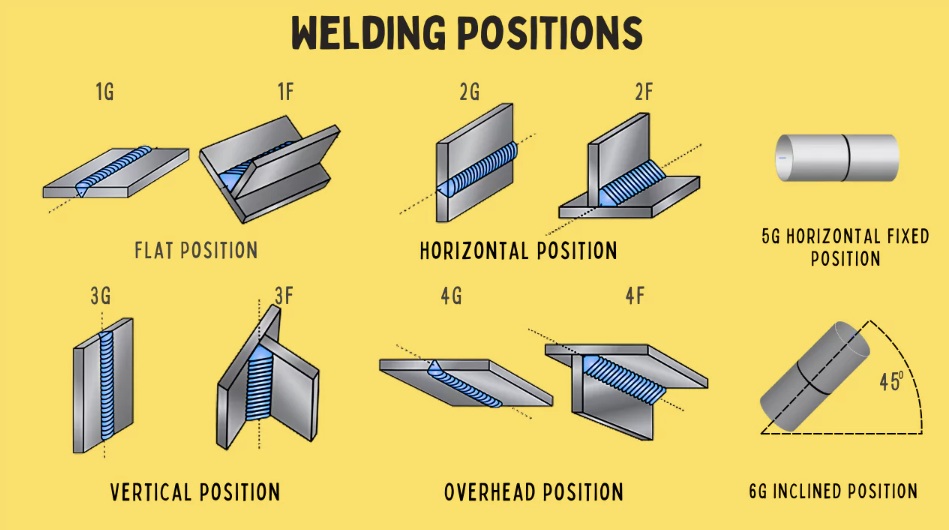

- Versatility: This quality, combined with the slag’s ability to support the weld puddle as it solidifies, makes the process suitable for all-position welding, including vertical and overhead applications (usually always needed)

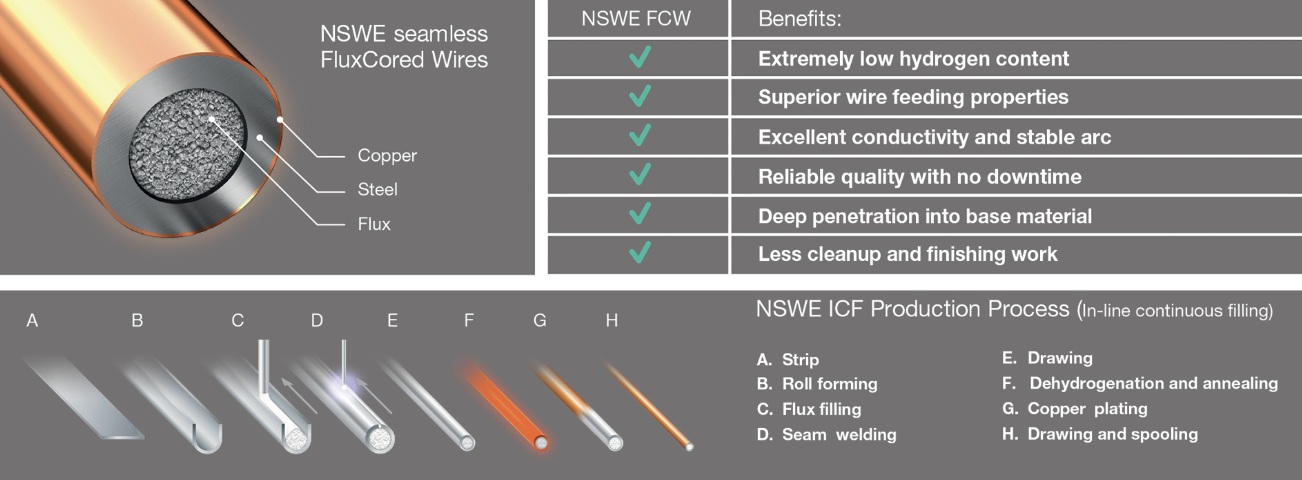

A seamless FCAW-G wire producing welds with very low diffusible hydrogen content, typical 2.8ml/100g weld metal.

- Yield Mpa strength: 530

- Tensile Mpsa strength: 590

Yield strength = the maximum stress steel can withstand before it begins to deform permanently. When the stress is removed, the steel will not return to its original shape if the yield strength is exceeded.

Tensile strength = the maximum stress steel can withstand while being pulled before it breaks

NOTE. Always make sure the yield and tensile strength of your steel and filler metal match up.

Can be used with all BOC ARGOSHIELD® Universal and Heavy argon/co2 shielding gas mixes (subject to plate thickness):

- 80% Argon / 20% Co2 (for welding thick plate from 10mm+ to 10mm+)

- 88% Argon / 12% Co2 (for welding thin up to 10mm to 10mm)

NST flux-cored wire has excellent weldability in all positions (inc. vertical down) and is extremely efficient in the root pass against ceramic backing.

The vertical down welding technique with gas-shielded flux-cored wire (FCAW-G) greatly reduces the risk of imperfections, and is primarily used for welding thin metals because the faster travel speed. This then helps prevent excessive heat input and burn-through.

FCAW-G Vertical Down Technique (3G Downhill):

- Reduce the voltage and amperage by approximately 10 to 15% compared to the settings used for a flat position weld

- The fast-freezing slag of gas-shielded flux-cored wire helps hold the weld puddle in place, allowing for slightly higher currents than some other processes.

- “If there’s slag, drag” – Maintain a slight travel angle (5 to 15 degrees) pointing the gun downward from the perpendicular position, in the direction of travel. This is often described as using a drag (backhand) technique, where you point the wire to the back of the weld puddle

- Begin at the top of the joint and move steadily downward, and weave whilst travelling. A slight side-to-side weaving motion can be used to control the bead shape and ensure proper fusion at the toes of the weld. For very thin metal, keep the wire on the leading edge of the weld puddle to avoid burn-through

- Watch the weld pool carefully. If it starts to overheat or drip excessively, briefly pull the gun away from the pool without breaking the arc, allowing the metal to solidify before continuing. The fast-freezing slag helps in managing the puddle against gravity

- The FCAW-G process produces a slag layer that must be removed after each pass

FCAW-G Vertical Up Technique (3G Uphill):

- Use a slight uphill travel angle (a slight drop from the perpendicular position), with the gun angled slightly towards the root for better penetration

- This will be a slower weld (alter settings to suit). Employ a steady travel speed, allowing the puddle to freeze and solidify behind you

SF-1A has a stable welding arc with less spatter and perfect bead surface. The flux cored wire has a clean, copper coated surface. Together with exact diameter and roundness it provides a stable and even wire feeding. This reduces wear and tear of liners and contact tips.

General purpose non-alloyed flux-cored MIG welding wire for shipbuilding and structures with impact test req. at -20 °C.