Product Description

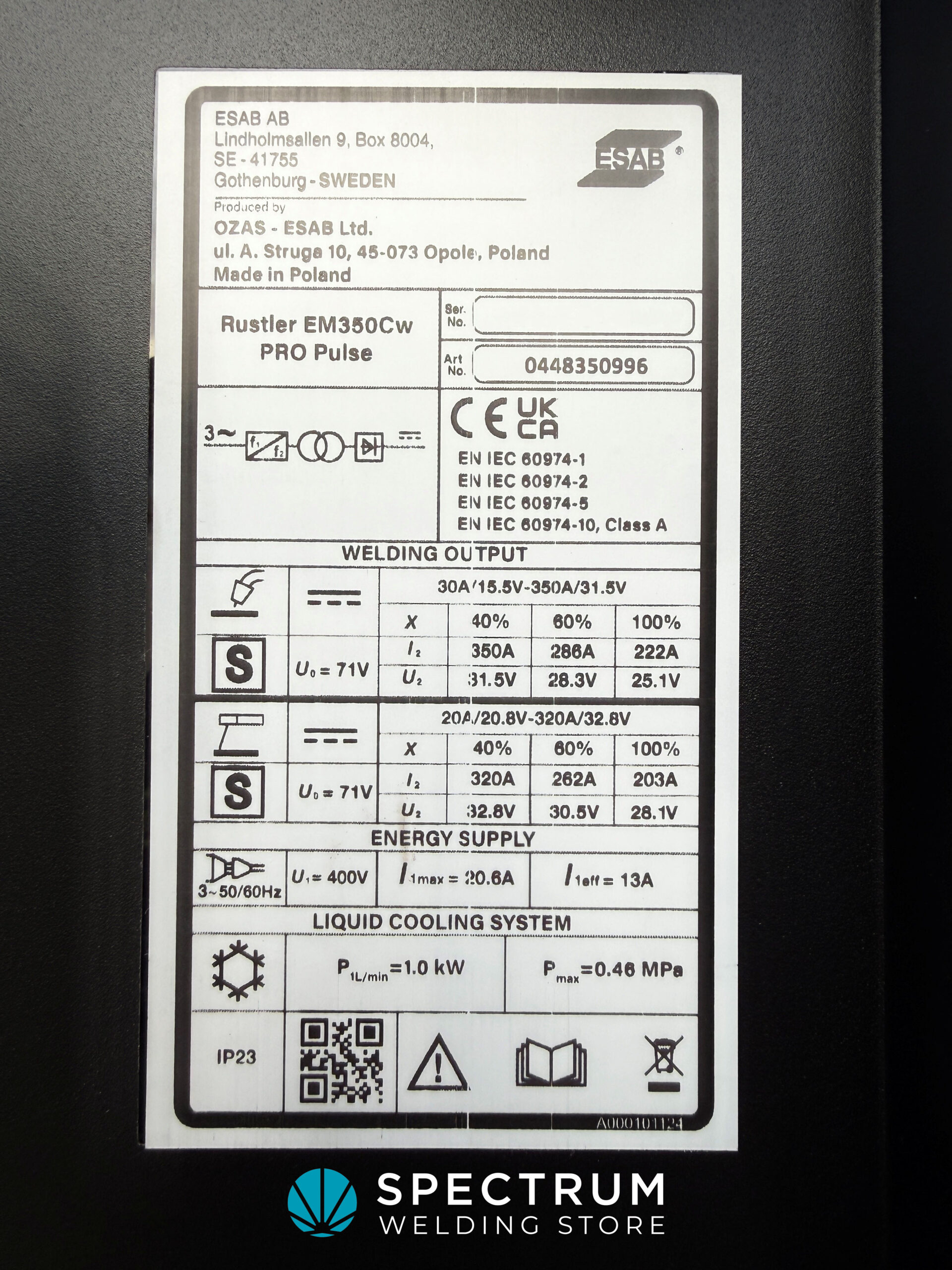

- Rustler EM 350 Synergic Pulse Compact Water Cooled MIG welder

- 3m x 6mm² 4-core SY power supply cable fitted

- On wheels with bottle trolley

- MB501 x 3m or 4mtr water cooled MIG torch

- 600amp x 5mtr 70mm² earth lead c/w Myking screw-type clamp

- 3mtr 20bar 6mm ID 3/8th nut argon hose

- 415V 32amp 4 or 5-pin red plug

- Assembled

- Weld tested

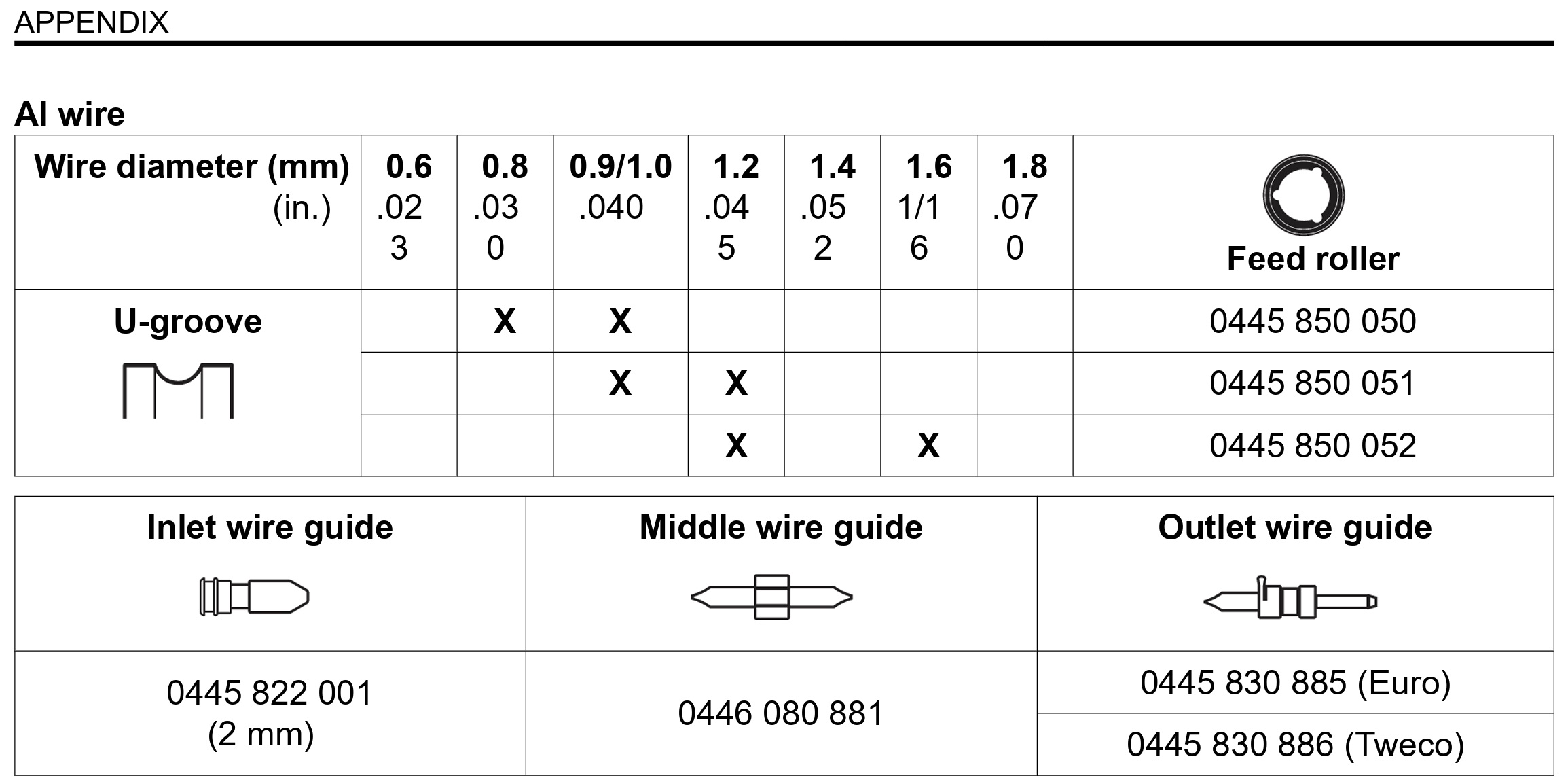

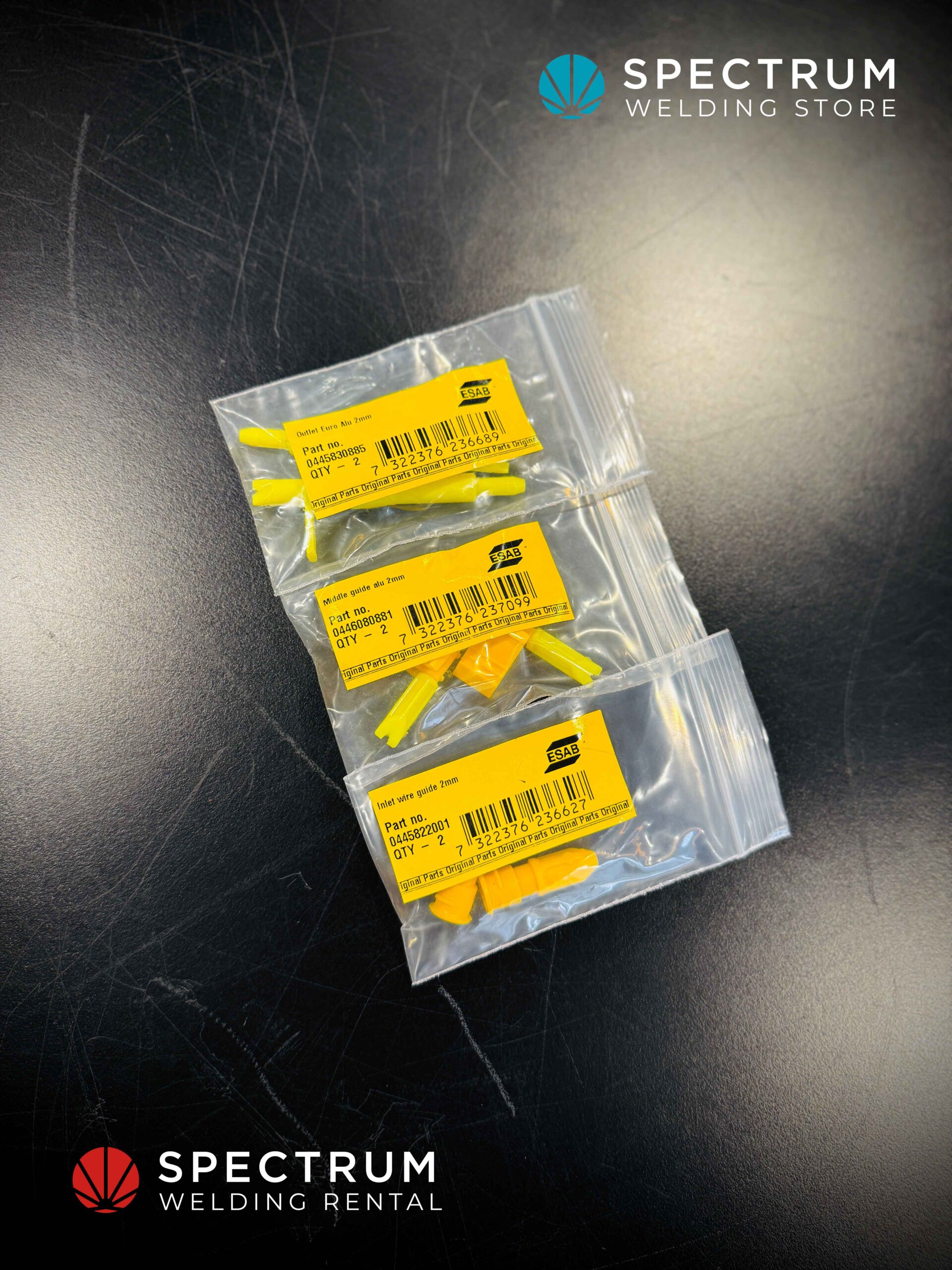

SETUP FOR EITHER OF THE BELOW:

- 4x, 1.0mm – 1.2mm V-Groove solid wire MIG wire drive rollers

- 4x, 1.2mm U-Groove aluminium wire MIG wire drive rollers

- 4x, 1.2mm knurled serrated groove flux-cored MIG wire drive rollers

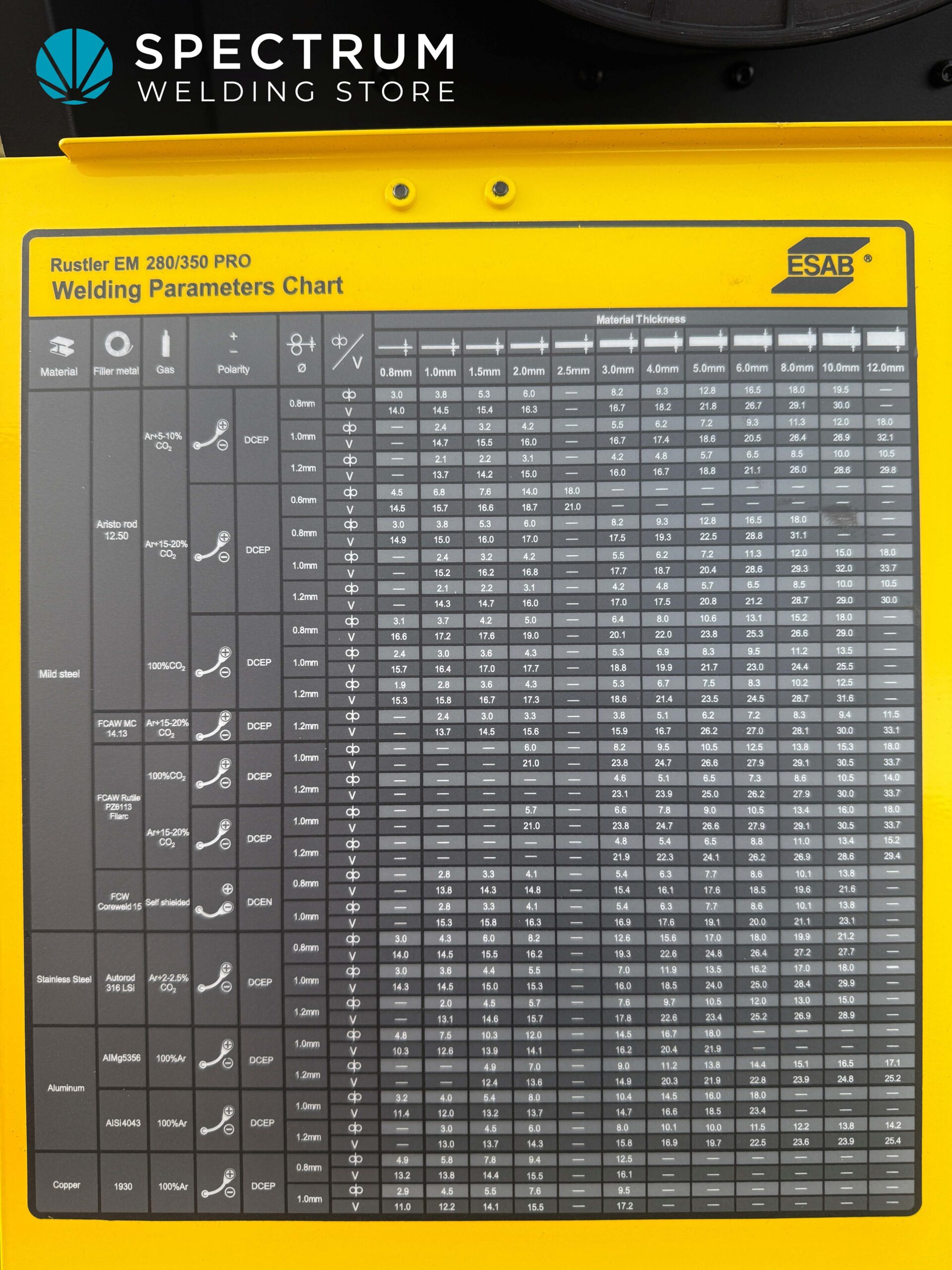

- Synergic Pulse MIG, Synergic MIG, Manual MIG, MMA stick

- Duty rating @ 100% – 222 amps

- Duty rating @ 60% – 262 amps

- Duty rating @ 40% – 350 amps

- Pulls 3-phase 24amps @ 350amps

- 32amp MCB D-rated trip needed

Argon flow guide (L/min) for welding aluminium 1.2mm wire @ 100 A to 300 A

(Use the “Start” value first, then trim ±2 L/min based on what you see.)

| Amps | Start (L/min) | Typical working range (L/min) |

| 100 | 16 | 14–18 |

| 120 | 17 | 15–19 |

| 140 | 18 | 16–20 |

| 160 | 19 | 17–21 |

| 180 | 20 | 18–22 |

| 200 | 21 | 19–23 |

| 220 | 22 | 20–24 |

| 240 | 23 | 21–25 |

| 260 | 24 | 22–26 |

| 280 | 25 | 23–27 |

| 300 | 26 | 24–28 |

- If you get porosity / grey, sooty edges / oxide peppering: go up +2 L/min, and check drafts (door/extraction), stickout, and torch angle.

- If the bead gets random porosity that doesn’t make sense: you might be too high (turbulence). Try down −2 L/min.

- If you’re welding near the open doorway or you can feel air movement: bump the whole table +2 to +4 L/min.

Part no. 0448350996